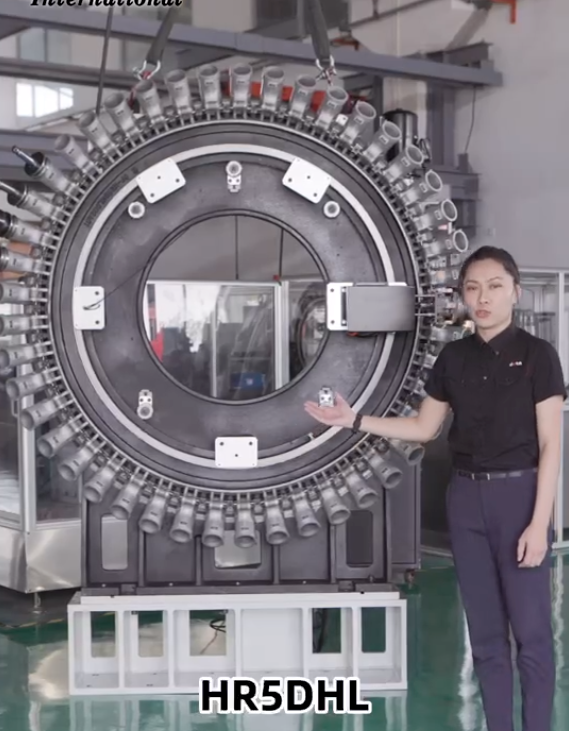

What I bring to you today is the disc-type radial tool magazine, model HR5DHL, which is applied to the horizontal processing machine in the form of positive T, let us take a look together!

What I bring to you today is the disc-type radial tool magazine, model HR5DHL, which is applied to the horizontal processing machine in the form of positive T, let us take a look together!

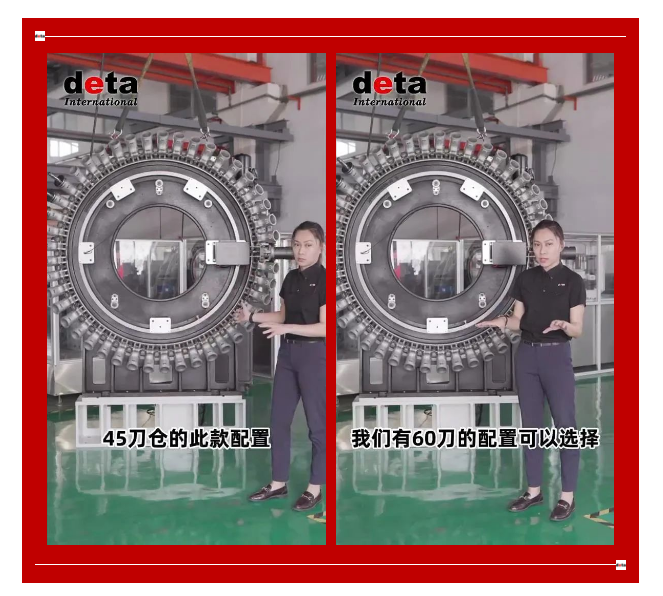

For the machine with single worktable, you can choose this model with 45 knife magazines. If it is a double workbench, we have 60 knife configurations to meet all the knife needs of customers and make customers satisfied! ! !

1.Tool magazine advantages

HR5DHL The maximum diameter of the tool adjacent to the tool is 150mm (millimeters), the empty adjacent tool is 250mm, the standard tool length is 350mm, the maximum tool weight of a single tool can reach 25KG, and the maximum loading weight of 45 tool bins is 400KG, if the environment meets the tool length The length can reach 550mm, the maximum loading weight of the 60-tool magazine specification is 600KG, and the environment meets the knife length up to 650mm. It is more usable than the general chain tool magazine, and can better meet the needs of large-scale tool processes such as deep holes and surface washing.

The structure of HR5DHL is different from the chain tool magazine, the production process is smoother, and its cost performance is also higher.

In the terminal site and the horizontal processing machine, if the conditions are met, the integrated floor-to-ceiling plan can bring a more stable knife-using environment and make your knife more durable!

2.Specifications

In addition to the general motor configuration, the cam tool change mechanism can also use a servo motor to achieve switching between light knife, heavy knife, and tool change speed, making the knife use more intelligent, fast and stable.

Next, I will introduce the performance data of this table with a knife arm radius of 325mm and light and heavy knives on the tool magazine:

The knife arm cam box is in the standard mode of 50 hertz (Hz), and the knife weight is 25KG, and the rotation is 2.8 seconds.

The rotation speed is increased to 60 hertz (Hz) through frequency conversion control, and the knife weight is within 15KG, and the self-rotation time is 2.2 seconds.

Servo motors can also be used as the driving source for the knife magazine. The 60-knife knife magazine is equipped with a servo motor as standard. The characteristics of the servo motor will greatly reduce the occasional unilateral load problem of random knife return. Generally, the performance of the near knife position of the motor is at 50Hz, about 0.8 seconds , when the servo motor is selected at 1000 revolutions (RPM), the adjacent knife position can be rotated in place in only 0.42 seconds. If this type of 45-knife magazine is equipped with a servo motor, the farthest knife can run 22 knife positions, less than ten It can be completed in seconds, which can greatly reduce the waiting time of the knife warehouse.

Home

Home Products

Products Telephone

Telephone Message

Message